In a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve into the world of advanced X-ray inspection and its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.A new era of food safety and qualityIn a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve intsleep aids uso the world of advanced X-ray inspection and its pivotal role in rev

across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve into the world of advanced X-ray inspection and its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.A new era of food safety and qualityIn a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve intsleep aids uso the world of advanced X-ray inspection and its pivotal role in rev olutionizing food safety, enhancing compliance, and safeguarding consumer trust.

olutionizing food safety, enhancing compliance, and safeguarding consumer trust.

The pursuit of producing safe, high-quality food products lies at the heart of every reputable food manufacturer. However, lurking in the shadows are numerous risks that threaten to compromise these goals. Foreign body contaminants and inconsistencies within products pose solgar calciumchallenges that demand swift and effective solutions Intelligent inspection software helps achieve this through automatic set-ups which detect the most hard-to-find contaminants and reject only the contaminated product. This reduces production waste and protects productivity.In a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technologis zinc citrate naturaly can help. In this era of innovation, we delve into the world of advanced X-ray inspection awhat is the dose for ferrous sulfatend its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.

Modular mechanical design features of advanced X-ray systems now allow full frontal access to common operations. This is complemented by easy-to-remove and reassemble vital components such as conveyor belts and lead-free, low-friction curtains. Product handling, cleaning, and service routines are now more efficient and require less time. In a fast-paced and ever-evolving world of manufactuzinc gluconate empty stomachring, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve into the world of advanced X-ray inspection and its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.Unparalleled advantagesIn a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve into the world of advanced X-ray inspection and its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.

Embracing X-ray inspection technology provides manufacturers with unparalleled advantages that elevate production processes to new heights. One benefit is process optimization. X-ray inspection systems can be connected to data management software, which provides real-time data and analytics that uncover hidden patterns and trends within production lines. By recording their production data digitally, manufacturers gain the power to optimize their processes, reduce waste, enhance efficiency, and maximize their uptime with minimal software investment costs.In a fast-paced and ever-evolving world of manufacturing, the safety and quality of our food is an absolute imperative. With the rise of consumer scrutiny through social media, and the heightened focus on food safety across the world, staying ahead of the game has never been more critical. Thankfully, game-changing smart X-ray inspection technology can help. In this era of innovation, we delve into the world of advanced X-ray inspection and its pivotal role in revolutionizing food safety, enhancing compliance, and safeguarding consumer trust.Furthermore, x-ray inspection technology when combined with vision inspection systems paves the way for comprehensive traceability systems. Through the automated inspection of label content including barcodes, manufacturers can effortlessly trace inspection results back to specific batches or l ots. This level of traceability proves vital in facilitating targeted product recalls and conducting thorough investigations when needed. With a clear path to follow, manufacturers can identify the root causes of issues, implement robust corrective actions and continuously elevate their food safety protocols.

ots. This level of traceability proves vital in facilitating targeted product recalls and conducting thorough investigations when needed. With a clear path to follow, manufacturers can identify the root causes of issues, implement robust corrective actions and continuously elevate their food safety protocols.

Food Safety with X-ray Inspection Systems

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

- Calcium Salt6 products

- Copper Salt1 product

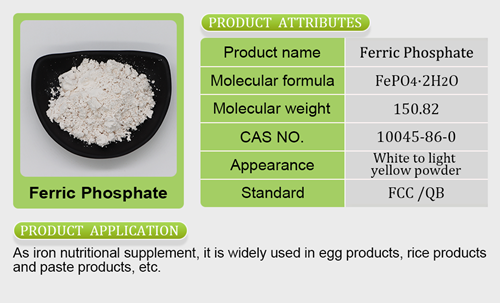

- Iron Salt7 products

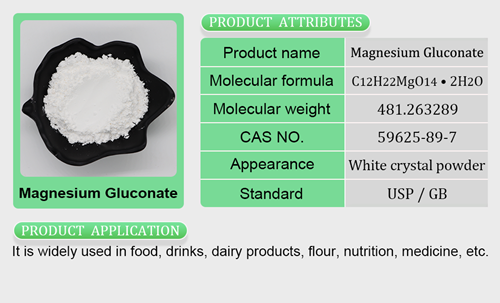

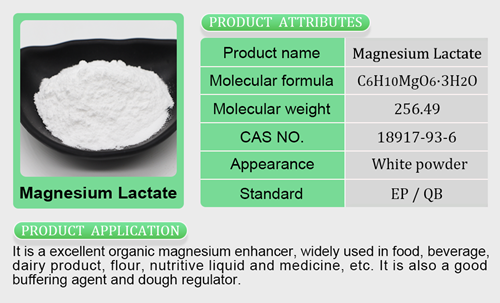

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products