BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.Supplying StePac with its Ultramid Ccycled, a chemically recycled polyamide 6, BASF will provide its partner greater flexibility to advance contact-sensitive packaging formats to a higher sustainable scopper and zinc supplementtandard wit hin the circular economy.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.The company specialises in developing advanced functional packaging solutions, is pioneering the use of chemically recycled plastics for the packaging of fresh perishables. The company was recently REDcert2 certified to incorporate chemically recycled polyamide 6 into its flexible, modified atmosphere packaging (MAP) products.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.Their two brands Xgo and Xtend are based on MAP technology with built-in humidity control which effectively slows respiration inside the packaging, delays the ageing processes, inhibits microbial decay, and preserves the qinlife magnesium glycinateuality and nutritional value of the produce during prolonged storage and long-haul shipments. Ultramid Ccycled will make up 30% of the packaging material, with options for integration at a higher percentage.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forc

hin the circular economy.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.The company specialises in developing advanced functional packaging solutions, is pioneering the use of chemically recycled plastics for the packaging of fresh perishables. The company was recently REDcert2 certified to incorporate chemically recycled polyamide 6 into its flexible, modified atmosphere packaging (MAP) products.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.Their two brands Xgo and Xtend are based on MAP technology with built-in humidity control which effectively slows respiration inside the packaging, delays the ageing processes, inhibits microbial decay, and preserves the qinlife magnesium glycinateuality and nutritional value of the produce during prolonged storage and long-haul shipments. Ultramid Ccycled will make up 30% of the packaging material, with options for integration at a higher percentage.BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forc es to create the next generation of sustainable packaging specifically for the fresh produce sector.Gary Ward, business development manager, StePac, said, “This alliance will help strike a balancxymogen coste between creating plastic packaging that is as eco-frien

es to create the next generation of sustainable packaging specifically for the fresh produce sector.Gary Ward, business development manager, StePac, said, “This alliance will help strike a balancxymogen coste between creating plastic packaging that is as eco-frien dly as possible to keep fresh produce longer through more prudent use of lean plastic films. These upgraded packaging formats will continue to maintain their role of significantly reducing food waste, a most important task considering that global food waste is responsible for about 8% of anthropogenic greenhouse gas emissions.”BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.With ChemCycling, BASF has been breaking new ground in the recycling of plastic waste. Chemical recycling primarily involves plastic waste that would have been used for enerpara que sirve el zinc glycinategy rectypes of chelated zincovery or landfilled. It complements mechanical recycling, accelerating a circular economy by yielding food-grade recycled plastic.

dly as possible to keep fresh produce longer through more prudent use of lean plastic films. These upgraded packaging formats will continue to maintain their role of significantly reducing food waste, a most important task considering that global food waste is responsible for about 8% of anthropogenic greenhouse gas emissions.”BASF SE -Ludwigshafen, Germany and StePac Ltd., -Tefen, Israel, have joined forces to create the next generation of sustainable packaging specifically for the fresh produce sector.With ChemCycling, BASF has been breaking new ground in the recycling of plastic waste. Chemical recycling primarily involves plastic waste that would have been used for enerpara que sirve el zinc glycinategy rectypes of chelated zincovery or landfilled. It complements mechanical recycling, accelerating a circular economy by yielding food-grade recycled plastic.

BASF and StePac Partner to Develop Sustainable Packaging for Shelf-life Extension of Fresh Produce

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

- Calcium Salt6 products

- Copper Salt1 product

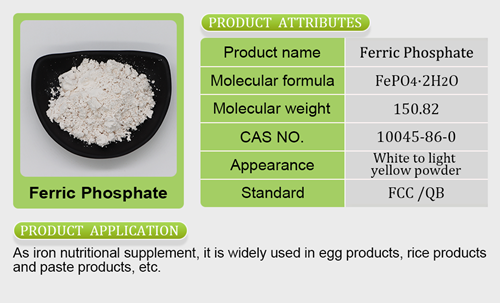

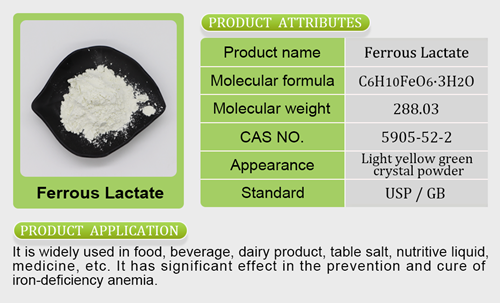

- Iron Salt7 products

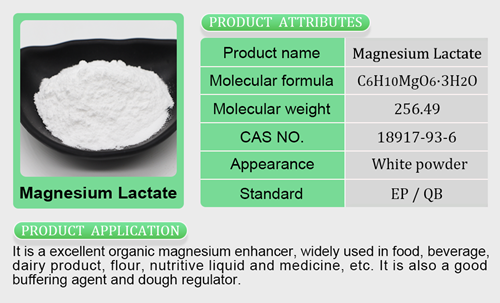

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products