In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.BillerudKorsnäs, one of the leading global packaging companies, has partnered with Oatly, the world’s original and largest oat drink company, to develop innovative packaging solutions for Oatly’s Singapore produced products.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.Oatly recently opened its first production facility in Asia to supply the nearby markets as part of the company’s global expansion. Products produced in the factory will be packed in boxes and transported on pallets during demanding climate conditions offering hot and humid weather which generates challenging logistics chains.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.The conventional packaging solution to manage high humidity is adding additional material for sturdier packaging. But the team at BillerudKorsnäs BoxLab found a different solution to ensure enwhat is the use of ferric pyrophosphatehanced sustainability performance while maintaining the high quality standards of Oatly’s secondary packaging. This innovative solution is based on the following principles:In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a repotassium magnesium citrate with vitamin b6duction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.· Minimizing damage and waste throughout the logistics chainIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packagimagnesium glycinate malateng by up to 50%*, compared to conventional packaging solutions.· Focus on resource efficiency – using as little material as possible and minimize water usageIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary pamagnesium malate and xanaxckaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.· Use packaging material that is recyclable and comes fro m renewable sourcesIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.· Transparency throughout the value chain securing renewable energy sourcesIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.This solution is the result of the partnership between Oatly and BillerudKorsnäs and proves the potential of addressing packagi

m renewable sourcesIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.· Transparency throughout the value chain securing renewable energy sourcesIn partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.This solution is the result of the partnership between Oatly and BillerudKorsnäs and proves the potential of addressing packagi ng challenges differently to ensure the sustainability performance is a key priority.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.“To challenge conventional packaging solutions for a sustainable future has long been the guiding star for BillerudKorsnäs. Oatly is a company that strives to produce sustainable and responsible products. We think alike doctor’s best magnesium glycinate redditin many ways,” says Henrik Ahlgren, Sales Director Asia &038; Pacific, BillerudKorsnäs.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conve

ng challenges differently to ensure the sustainability performance is a key priority.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.“To challenge conventional packaging solutions for a sustainable future has long been the guiding star for BillerudKorsnäs. Oatly is a company that strives to produce sustainable and responsible products. We think alike doctor’s best magnesium glycinate redditin many ways,” says Henrik Ahlgren, Sales Director Asia &038; Pacific, BillerudKorsnäs.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conve ntional packaging solutions.Packaging material based on strong primary fibres can make a remarkable difference in demanding logistics chains. The reduction in secondary packaging material with up to 35% will generate substantial savings of packaging material per year.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.The renewable paper material originates from responsibly managed forests.**In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.After use, the packaging can be recycled and used for less demanding packaging multiple times.***

ntional packaging solutions.Packaging material based on strong primary fibres can make a remarkable difference in demanding logistics chains. The reduction in secondary packaging material with up to 35% will generate substantial savings of packaging material per year.In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.The renewable paper material originates from responsibly managed forests.**In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.After use, the packaging can be recycled and used for less demanding packaging multiple times.***

BillerudKorsnäs Innovative Solution on Secondary Packaging helps Oatly Cut Packaging Carbon Footprint by Half

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

- Calcium Salt6 products

- Copper Salt1 product

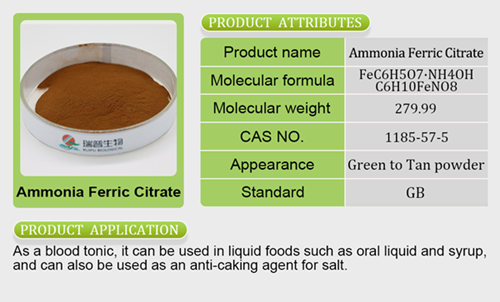

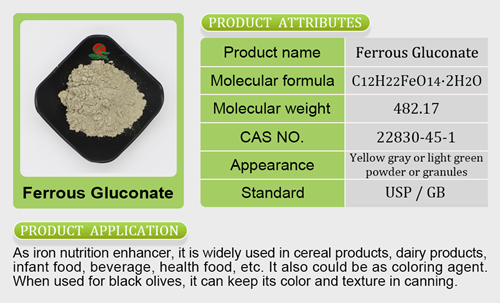

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

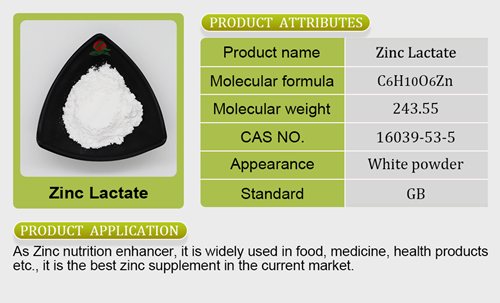

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products