Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Producing large quantities of popular fast-food items such as chicken nuggets with consistent, repeatable results, every time is a highly sensitive process. As leading global brands place increased emphasis on demanding specifications for product quality, this has become a fine art. Any marginal deviation on a production line can affect the quality, and it already starts at the basis of the product &8211; the viscosity of the meat mixture. Not having that under full control will ultimately affect the finished product at the end of the process. Technology experts from GEA have designed a unique solution on the market, called Batch2Flow, that secures the production process, saves energy and water and significantly reduces the use of cleaning chemicals.Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesa ving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainawhen to take ferrous fumaratebility of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Automate demanding processesConvenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more conveniencferrous fumarate 210mg p or pome options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Maintaining a safe temperature of the ingredients is especially crucial in the process. Not only does this help to prevent spoilage, it also helps to ensure that the optimum viscosity of the meat mixture is maintained throughout the initial forming process, leading to successful, perfectly created nuggets. But that takes a lot of energy use, specialized chilled rooms to store meat between the mixing and forming stages of the process. In addition, the process is relatively complicated and susceptible to human mistakes.To move the mixed product from the mixer to the former, most producers use standard 200L trollies. It’s hard physical work, and inevitably, there’s a time delay between the meat leaving the mixer and entering the former. At this point, it depends on the operator to ensure that no contamination enters the mix.Convenience food has been a trend topic in the food industry for many years now.

ving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainawhen to take ferrous fumaratebility of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Automate demanding processesConvenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more conveniencferrous fumarate 210mg p or pome options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Maintaining a safe temperature of the ingredients is especially crucial in the process. Not only does this help to prevent spoilage, it also helps to ensure that the optimum viscosity of the meat mixture is maintained throughout the initial forming process, leading to successful, perfectly created nuggets. But that takes a lot of energy use, specialized chilled rooms to store meat between the mixing and forming stages of the process. In addition, the process is relatively complicated and susceptible to human mistakes.To move the mixed product from the mixer to the former, most producers use standard 200L trollies. It’s hard physical work, and inevitably, there’s a time delay between the meat leaving the mixer and entering the former. At this point, it depends on the operator to ensure that no contamination enters the mix.Convenience food has been a trend topic in the food industry for many years now.  But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Industrial mixers work quickly, so before the first trolley can be loaded into the former, the next batch is filling up another trolley. So, one person has to quickly move the trolleys into a cold store while another moves them one by one from the cold store to the former. In the meantime, the optimum temperature and viscosity of the mix is starting to deteriorate as it moves towards the ambient temperature. And, if a trolley gets forgotten, it results in costly wastage as the contents will have to be disposed of. In the worst-case scenario, a forgotten trolley could be mistakenly loaded into the former, seriously risking the food safety of the product. Even when all goes to plan there is wastage, as residue remains within the trolleys, so these have to be cleaned repeatedly with hot water and chemicals.Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life wilmagnesium malate 1000mg nowl get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Batch2Flow – automated link between mixing and formingConvenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Batch2Flow eliminates these difficulties by moferric phosphate tabletving the mix seamlessly and rapidly along a conveyor system from the mixers straight into the former, and the mixers have special unloading steps to allow controlled portion delivery onto the conveyor. As a result, it will be at precisely the right temperature and viscosity when it reaches the former. No energy-consuming cold stores are needed, food waste is avoided, cleaning costs are significantly reduced, and there is full traceability as nothing is removed from the line.Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was befozonated magnesium oxide vs magnesium citrateore and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?With Batch2Flow GEA experts have designed the mis

But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Industrial mixers work quickly, so before the first trolley can be loaded into the former, the next batch is filling up another trolley. So, one person has to quickly move the trolleys into a cold store while another moves them one by one from the cold store to the former. In the meantime, the optimum temperature and viscosity of the mix is starting to deteriorate as it moves towards the ambient temperature. And, if a trolley gets forgotten, it results in costly wastage as the contents will have to be disposed of. In the worst-case scenario, a forgotten trolley could be mistakenly loaded into the former, seriously risking the food safety of the product. Even when all goes to plan there is wastage, as residue remains within the trolleys, so these have to be cleaned repeatedly with hot water and chemicals.Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life wilmagnesium malate 1000mg nowl get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Batch2Flow – automated link between mixing and formingConvenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was before and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?Batch2Flow eliminates these difficulties by moferric phosphate tabletving the mix seamlessly and rapidly along a conveyor system from the mixers straight into the former, and the mixers have special unloading steps to allow controlled portion delivery onto the conveyor. As a result, it will be at precisely the right temperature and viscosity when it reaches the former. No energy-consuming cold stores are needed, food waste is avoided, cleaning costs are significantly reduced, and there is full traceability as nothing is removed from the line.Convenience food has been a trend topic in the food industry for many years now. But after COVID-19 restrictions industry experts are of the opinion the pace of life will get busy or even busier as it was befozonated magnesium oxide vs magnesium citrateore and requires more convenience options. Consumers will expect timesaving, hygienic and adventurous convenience food, drink, and foodservice. In the next few years, brands will also be challenged to respond to new definitions of quality and sustainability of their products. Can food manufacturers do anything to reduce the impact on the environment from their production processes, whilst still maintaining the product quality we all expect?With Batch2Flow GEA experts have designed the mis sing link between mixing and forming, that comes with additional benefits for food safety too. GEA noticed that the cold metal trolleys in a forming line had a tendency to attract moisture – condensation which has the potential to drip off and contaminate the mix when the trolley is tipped upside down and emptied into the former. And in tipping the trolleys upside down, the four wheels which have been on the floor are exposed above the product, time and time again. Batch2Flow completely removes these risks, whilst minimizing waste and reducing energy consumption.

sing link between mixing and forming, that comes with additional benefits for food safety too. GEA noticed that the cold metal trolleys in a forming line had a tendency to attract moisture – condensation which has the potential to drip off and contaminate the mix when the trolley is tipped upside down and emptied into the former. And in tipping the trolleys upside down, the four wheels which have been on the floor are exposed above the product, time and time again. Batch2Flow completely removes these risks, whilst minimizing waste and reducing energy consumption.

Automation Within Food Processing Ensures Quality, Reduces Food Waste and Emissions

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

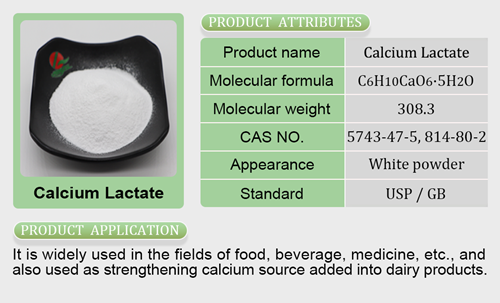

- Calcium Salt6 products

- Copper Salt1 product

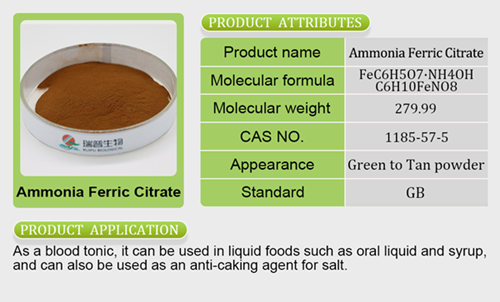

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

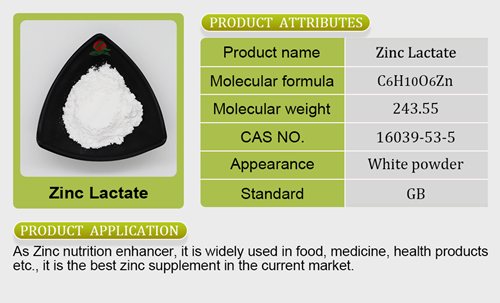

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products