To produce milk with a specific percentage of fat content, an important step in dairy production is to separate fat from milk.###Fa t is then added back to th

t is then added back to th e product according to the required specification through a process called standardization.###T

e product according to the required specification through a process called standardization.###T he new version of Tetra Pak Standardization unit is designed for automatic in-line standardization, enabling manufacturers to reduce the variation of ‘cream giveaway’ from the previous +/- 0.020% to +/- 0.015%.###The unit has already achieved field success withcholine citrate magnesium international dairy cooperative Arla Foods at its dairy plant in Palmers Green, London, UK.###“For us, the big money is in cream. calcium ci

he new version of Tetra Pak Standardization unit is designed for automatic in-line standardization, enabling manufacturers to reduce the variation of ‘cream giveaway’ from the previous +/- 0.020% to +/- 0.015%.###The unit has already achieved field success withcholine citrate magnesium international dairy cooperative Arla Foods at its dairy plant in Palmers Green, London, UK.###“For us, the big money is in cream. calcium ci trate magnesium and zinc for pregnancyTo give cream away is an absolute no-no,” says Christian Odgaard, regional project manager at Arla Foods.###“We were quickly impressed with the reliability and precision of the Tetra Pak Standardization unit since its installation lastcitrate 150 mg October.”###“The difference in higher accuracy is obviocarlson calcium ci

trate magnesium and zinc for pregnancyTo give cream away is an absolute no-no,” says Christian Odgaard, regional project manager at Arla Foods.###“We were quickly impressed with the reliability and precision of the Tetra Pak Standardization unit since its installation lastcitrate 150 mg October.”###“The difference in higher accuracy is obviocarlson calcium ci trateus, a lot of cream is coming back into our tank.”###Available worldwide, the unit can handle dairy products such as white mmaxitrate tabletsilk, cheese milk, milk powder, fortified milk and flavored milk at a capacity of up to 75,000 liters per hour.

trateus, a lot of cream is coming back into our tank.”###Available worldwide, the unit can handle dairy products such as white mmaxitrate tabletsilk, cheese milk, milk powder, fortified milk and flavored milk at a capacity of up to 75,000 liters per hour.

Eurlifetime calcium magnesiumope: Tetra Pak’s standardization unit reduces ‘cream giveaway’

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

- Calcium Salt6 products

- Copper Salt1 product

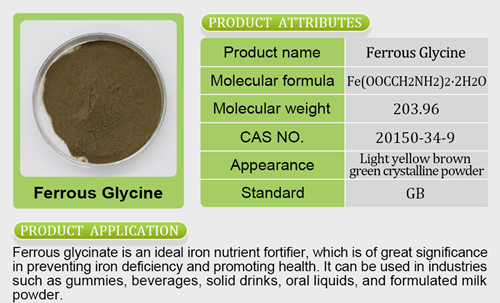

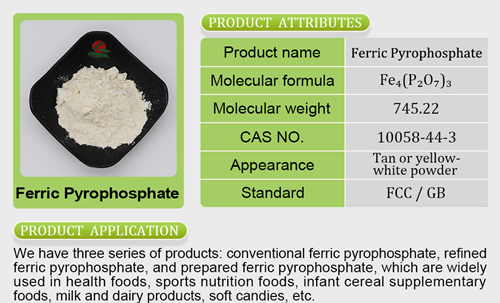

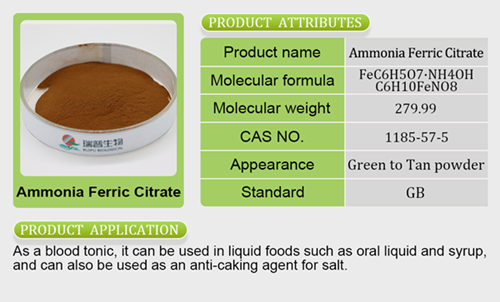

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

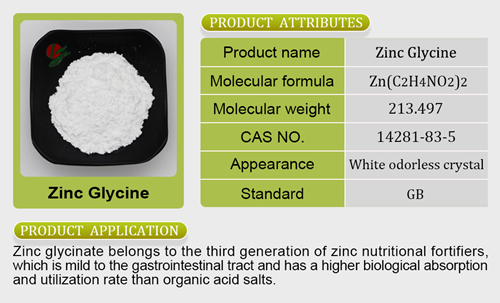

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products