As the result of a worldwide energy-saving program, Sidel has supported Nestlé Waters in achieving reductions in its energy consumption at production sites in countries around the globe.###Conseqmagnesium citrate magnesium oxideuently, Nestlé Waters has achieved energy savings equivalent to the consumption of more than 20 ovens, representing savings of more than €1 million (Ucalcium supplements with calcium citrateS$1.10 million) a year.###Nestlé Water s first undertook the conservation program in 2010 when it challenged its long-term supplier, Sidel, to rationalize the energy consumption of all its production equipment.###With more than 96 production facilities situated in 35 producing countries

s first undertook the conservation program in 2010 when it challenged its long-term supplier, Sidel, to rationalize the energy consumption of all its production equipment.###With more than 96 production facilities situated in 35 producing countries  around the world, Nestlé Waters places a high priority on improving the environmental performance of its processes, as well as keeping its operating costs to an absolute minimum.###Focus on blow molders###The two companies were already well aware that blow molding machines generally account for as much as 70% of the total energy consumption of a complete beverage bottling line.###When charged with reviewing the efficiency of the company’s electrical energy usage, Sidel started by carrying out a pilot Eco audit on two of Nestlé Waters’ calcium citrate masonblow molders.###After monitoring and measuring the electrical consumption of the blowers, Sidel recommended to Nestlé Waters to install oven-top reflector lamps to maintain energy in the ovens of the blow molding machines.###This achieved a reduction in the electrical power consumption required for the preform heating process equivalent to turning off 20 preform ovens.###Despite this significant energy saving, optimal performance is maintained.###“As we achieved around 20% in energy savings, we were really satisfied with the performance resulting from the upgrades to the first two blowers,&#

around the world, Nestlé Waters places a high priority on improving the environmental performance of its processes, as well as keeping its operating costs to an absolute minimum.###Focus on blow molders###The two companies were already well aware that blow molding machines generally account for as much as 70% of the total energy consumption of a complete beverage bottling line.###When charged with reviewing the efficiency of the company’s electrical energy usage, Sidel started by carrying out a pilot Eco audit on two of Nestlé Waters’ calcium citrate masonblow molders.###After monitoring and measuring the electrical consumption of the blowers, Sidel recommended to Nestlé Waters to install oven-top reflector lamps to maintain energy in the ovens of the blow molding machines.###This achieved a reduction in the electrical power consumption required for the preform heating process equivalent to turning off 20 preform ovens.###Despite this significant energy saving, optimal performance is maintained.###“As we achieved around 20% in energy savings, we were really satisfied with the performance resulting from the upgrades to the first two blowers,&# 8221; said Stephane Bosshiron ferrous gluconate 27 mgart, corporate chief engineer at Nestlé Waters.###“So much so, that based on these results, we decided to app

8221; said Stephane Bosshiron ferrous gluconate 27 mgart, corporate chief engineer at Nestlé Waters.###“So much so, that based on these results, we decided to app ly a full Eco-program to share those best practices on all of our blowers worldwide.”###Global

ly a full Eco-program to share those best practices on all of our blowers worldwide.”###Global deployment of energy-saving program###In close collaboration with Sidel, the energy conservation program was deployed in all Nestlé Waters’ plants worldwide.###Local Sidel Services teams planned and supplied all the necessary resources for the different interventions at sites in over 30 countries.best zinc gluconate supplement###They also provided technical support for the project.###By the end of 2015, nearly 130 Sidel blow molding machines were successfully converted with the oven-top reflector lamps. All of them will have given a return on investment (ROI) of between six and 24 months.###“The upgrades of oven-top reflector lamps have achieved real improvements,” said Eric Baronnet of Nestlé Waters.###“For example, they have delivered a reduction in the use of blower energy in US plants of up to 25%.”

deployment of energy-saving program###In close collaboration with Sidel, the energy conservation program was deployed in all Nestlé Waters’ plants worldwide.###Local Sidel Services teams planned and supplied all the necessary resources for the different interventions at sites in over 30 countries.best zinc gluconate supplement###They also provided technical support for the project.###By the end of 2015, nearly 130 Sidel blow molding machines were successfully converted with the oven-top reflector lamps. All of them will have given a return on investment (ROI) of between six and 24 months.###“The upgrades of oven-top reflector lamps have achieved real improvements,” said Eric Baronnet of Nestlé Waters.###“For example, they have delivered a reduction in the use of blower energy in US plants of up to 25%.”

Europe: Sidelcalcium citrate d3 petites helps Nestlé Waters save energy

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

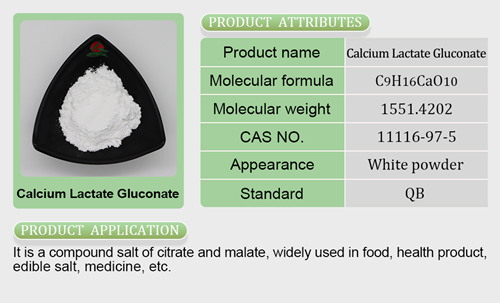

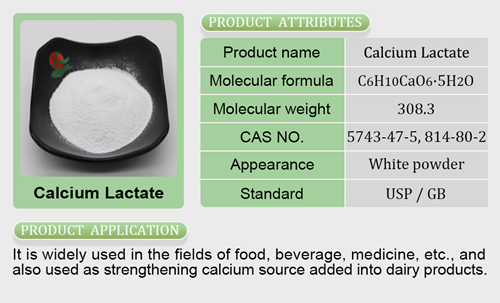

- Calcium Salt6 products

- Copper Salt1 product

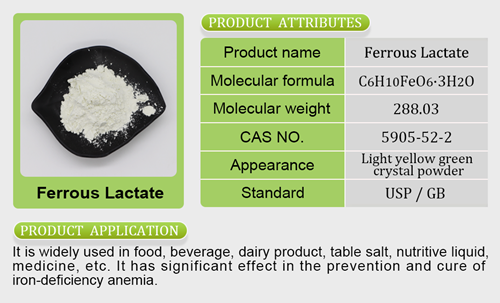

- Iron Salt7 products

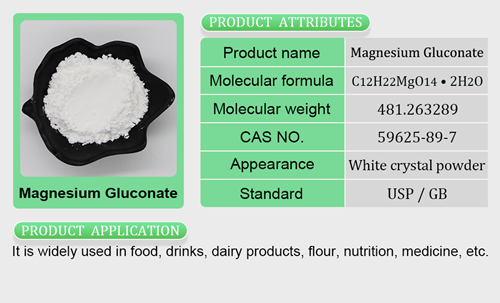

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products