EU-funded researchers have adapted two biodegradable plastics made from crop waste for use as food packaging.###Most plastics currently used to package food are made from petrochemicals and are not biodegradable.###While industry has been seeking greener, sustainable alternatives the solution has so far been elusive – food packaging must meet high quality and safety standards.###To help, the European Union has been funding research projects to develop greener, sustainable alternatives, cut waste and boost Europe’s competitiveness in alternative plastics.###Promising candidates have emerged from the SUSFOFLEX project, which produced novel packaging using polylactic acid (PLA), and from SUCCIPACK, which adapted polybutylene succinate (PBS) for use by the food industry.###PLA and PBS can be made from by-products left over from farming crops such as wheat, corn and beetroot.###The two plastics are biodegradable – they can be broken down into their basic constituents, such as water, carbon dioxide and compost.###Both projects laid the groundwork for the commercialization of PLA and PBS for food packaging.###Innovative package###SUSFOFLEX resulted in prototypes of a PLA-based plastic, an innovative pack design, and two types of sensors to indicate whether the food inside is safe to eat.###The project targeted pre-cut fruit products, an important  market segment.##magnesium glycinate and citrate supplement#“These new active, intelligent and sustainable solutions are consumer-oriented, ensure the safety and quality of food, cut food losses, and reduce the environmental impact of food packaging,” says project coordinator Geza Toth of the University of Oulu in Finland.###The plastic could be adapted for other types of foods, such as cut vegetables, and meat, he adds.###SUSFOFLEX developed techniques to combine

market segment.##magnesium glycinate and citrate supplement#“These new active, intelligent and sustainable solutions are consumer-oriented, ensure the safety and quality of food, cut food losses, and reduce the environmental impact of food packaging,” says project coordinator Geza Toth of the University of Oulu in Finland.###The plastic could be adapted for other types of foods, such as cut vegetables, and meat, he adds.###SUSFOFLEX developed techniques to combine PLA with cellulose extracted from wheat straw, an agricultural by-product, and with a natural antioxidant obtained from waste orange peels.###Antioxidants extend shelf-life by reducing the interaction of oxygen with the cut surfaces of the packaged fruit.###This interaction, called oxidation, blemishes the cut surfaces – turning apple slices brown for example – and speeds iron gluconateup rotting.###SUSFOFLEX’s plastic also incorporates nanoclay, which are tiny mineral particles, and silver nanoparticles.###The nanoclay further strengthens the PLA and helps prevent the entry of oxygen into the package. Silver nanoparticles inhibit the growth of pathogens in the package,citracal sr improving safety.###As a demonstration, the project used the PLA-based plastic for new packaging it designed for fruit salads

PLA with cellulose extracted from wheat straw, an agricultural by-product, and with a natural antioxidant obtained from waste orange peels.###Antioxidants extend shelf-life by reducing the interaction of oxygen with the cut surfaces of the packaged fruit.###This interaction, called oxidation, blemishes the cut surfaces – turning apple slices brown for example – and speeds iron gluconateup rotting.###SUSFOFLEX’s plastic also incorporates nanoclay, which are tiny mineral particles, and silver nanoparticles.###The nanoclay further strengthens the PLA and helps prevent the entry of oxygen into the package. Silver nanoparticles inhibit the growth of pathogens in the package,citracal sr improving safety.###As a demonstration, the project used the PLA-based plastic for new packaging it designed for fruit salads  and similar products.###The package has a reservoir to collect liquid exuded by the fruit, thus increasing shelf-life and maintaining quality.###Safety sam’s club magnesium citratesensors###To complete the package, the project team also developed two types of miniature safety sensors to detect when cut fruit could be unsafe to eat.###Both sensors can be put on a package label using special printing techniques and inks.###One has a tiny wire that is inserted through the package and senses the level of ethanol inside. Ethanol is produced as microorganisms start to degrade fruit and make it unsafe to

and similar products.###The package has a reservoir to collect liquid exuded by the fruit, thus increasing shelf-life and maintaining quality.###Safety sam’s club magnesium citratesensors###To complete the package, the project team also developed two types of miniature safety sensors to detect when cut fruit could be unsafe to eat.###Both sensors can be put on a package label using special printing techniques and inks.###One has a tiny wire that is inserted through the package and senses the level of ethanol inside. Ethanol is produced as microorganisms start to degrade fruit and make it unsafe to  eat.###The information on ethanol levels is stored on a radio-frequency identification (RFID) tag on the package.###magnesiu

eat.###The information on ethanol levels is stored on a radio-frequency identification (RFID) tag on the package.###magnesiu m citrate magnesium glycinateAn electronic device can receive this information using radio signals transmitted to the tag – signaling to suppliers when their products are no longer fit for consumption.###The second SUSFOFLEX sensor signals this information via a color change.###It changes color when cut fruit has been exposed to a temperature above 15°C.###This indicates that at some time along the supply chain, the product has not been kept sufficiently chilled to remain safe.###While SUSFOFLEX ended in December 2014, the industrial partners in the project plan to further develop the PLA-based plastic, the new package design and the sensors before commercialization, says Toth.###PBS – another solution###Meanwhile the SUCCIPACK project demonstrated a production process to produce PBS-based plastics suitable for food packaging.###The innovations included a process to improve the resistance of PBS-based packaging to oxygen and water – resulting in increased shelf-life and food safety.###SUCCIPACK, which ended in December 2014, also produced demonstration film wrapping and containers (trays) for packaging cheese, meat, fish and vegetarian food products.###Based on its research, the project also developed guidelines recommending ways industry could further develop PBS-based plastics to the commercialization stage.###The project forecasts that its research could help European industry, especially small businesses, leapfrog over other competitors vying to produce PBS-based food packaging.

m citrate magnesium glycinateAn electronic device can receive this information using radio signals transmitted to the tag – signaling to suppliers when their products are no longer fit for consumption.###The second SUSFOFLEX sensor signals this information via a color change.###It changes color when cut fruit has been exposed to a temperature above 15°C.###This indicates that at some time along the supply chain, the product has not been kept sufficiently chilled to remain safe.###While SUSFOFLEX ended in December 2014, the industrial partners in the project plan to further develop the PLA-based plastic, the new package design and the sensors before commercialization, says Toth.###PBS – another solution###Meanwhile the SUCCIPACK project demonstrated a production process to produce PBS-based plastics suitable for food packaging.###The innovations included a process to improve the resistance of PBS-based packaging to oxygen and water – resulting in increased shelf-life and food safety.###SUCCIPACK, which ended in December 2014, also produced demonstration film wrapping and containers (trays) for packaging cheese, meat, fish and vegetarian food products.###Based on its research, the project also developed guidelines recommending ways industry could further develop PBS-based plastics to the commercialization stage.###The project forecasts that its research could help European industry, especially small businesses, leapfrog over other competitors vying to produce PBS-based food packaging.

Europe: Researchers demagnesium citrate liquid where to buyliver green plastics for food packaging

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

- Calcium Salt6 products

- Copper Salt1 product

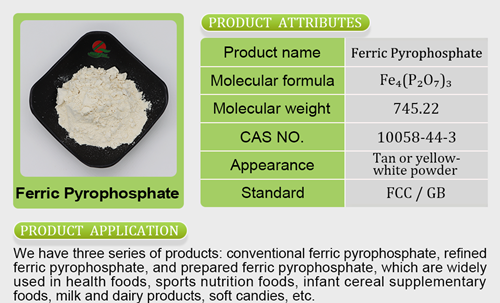

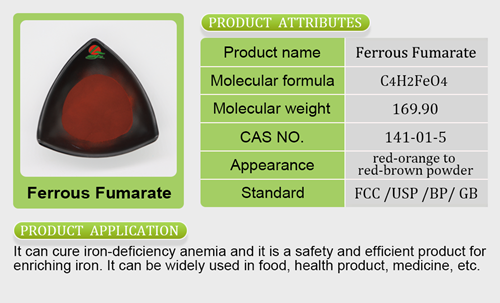

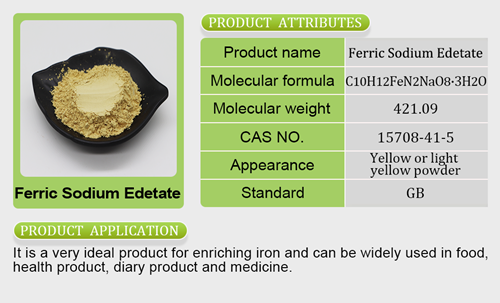

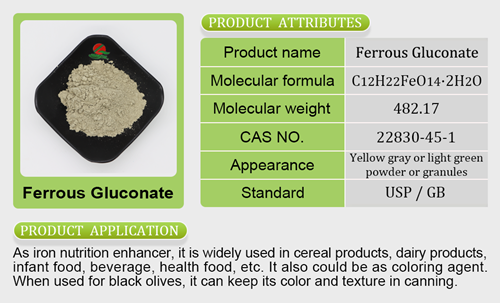

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products