Linpac has upgraded selected thermoforming product lines from conventional heating systems to Ceramicx infra red (IR)-based heating at its St Helens facility in the UK.###IR radiation can sometimes be described as ‘sunshine without light’.###When applied correctly in heat work it can result in substantial improvements in process accuracy and energy savinchewable calcium citrate 1200 mgg.###However, IR heat science is still relatively misu nderstood and misapplied in many industrial sectors.###Linpac supplier Ceramicx uses proprietary know-how and instrumentation to accurately map the invisible IR heat flux spectrum thus enabling the company to build the lowest energy IR heat source and control.###In order to enable and

nderstood and misapplied in many industrial sectors.###Linpac supplier Ceramicx uses proprietary know-how and instrumentation to accurately map the invisible IR heat flux spectrum thus enabling the company to build the lowest energy IR heat source and control.###In order to enable and  prove t

prove t he new IR heat system, a substantial amount of study work was undertaken prior to, and during, the St Helens upgrade process.###These studies were commissioned for LINPAC bybest way to take magnesium citrate the IR heating supplier Ceramicx and were conducted at the St Helens site by Dr. Robin Kent of Tangram Technology, who measured the detailed differences in the heat and energy performa

he new IR heat system, a substantial amount of study work was undertaken prior to, and during, the St Helens upgrade process.###These studies were commissioned for LINPAC bybest way to take magnesium citrate the IR heating supplier Ceramicx and were conducted at the St Helens site by Dr. Robin Kent of Tangram Technology, who measured the detailed differences in the heat and energy performa nce between two identical thermoforming lines.###The comparisons between the Ceramicx optimized IR system and the existing IR thermoforming lines were undertaken using identical tools, products and cycle times.###Both Linpac lines manufacture the same EPS packaging products for the food service industries.###Under test, the Ceramicx IR heating systems showed a decrease in the average power drawn from 56.16 kW to 32.85 kW, representing a 41.6% reduction in energy.###Figures showed a direct comparison between the two oven systems.###With the machine base loads remove

nce between two identical thermoforming lines.###The comparisons between the Ceramicx optimized IR system and the existing IR thermoforming lines were undertaken using identical tools, products and cycle times.###Both Linpac lines manufacture the same EPS packaging products for the food service industries.###Under test, the Ceramicx IR heating systems showed a decrease in the average power drawn from 56.16 kW to 32.85 kW, representing a 41.6% reduction in energy.###Figures showed a direct comparison between the two oven systems.###With the machine base loads remove d, the Ceramicx IR-based system thperbedaan zinc picolinate dan zinc gluconateen showed a measured energy saving of 45.8%.###Both machines were directly comparable and both are part of two in-line and fast cycling systems at the customer, loaded with the same tools.###In plastics thermoforming production these heatcalcium carbonate same as calciuming legacy issues to be overcome can often include burn outs, electrical faults and problems with older style and non-directional heating.###Tubular and magnesium filled heating solutions; black rod heating and other kinds of non-infrared sources can all make a contribution to inexact systems of thermoforming production, quality issues and – above all – to a waste of energy and electricity cost.###This kind of heating becomes uncontrollable in a completely enclmagnesium lactate 84 mgosed system or oven.###Thermoforming operators are being continually forced to ramp up the power and the input electricity in order to try and maintain an even temperature.

d, the Ceramicx IR-based system thperbedaan zinc picolinate dan zinc gluconateen showed a measured energy saving of 45.8%.###Both machines were directly comparable and both are part of two in-line and fast cycling systems at the customer, loaded with the same tools.###In plastics thermoforming production these heatcalcium carbonate same as calciuming legacy issues to be overcome can often include burn outs, electrical faults and problems with older style and non-directional heating.###Tubular and magnesium filled heating solutions; black rod heating and other kinds of non-infrared sources can all make a contribution to inexact systems of thermoforming production, quality issues and – above all – to a waste of energy and electricity cost.###This kind of heating becomes uncontrollable in a completely enclmagnesium lactate 84 mgosed system or oven.###Thermoforming operators are being continually forced to ramp up the power and the input electricity in order to try and maintain an even temperature.

Europe: Linpac upgrades to green IR heating at fcalcium citrate tablets 500mgacility

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

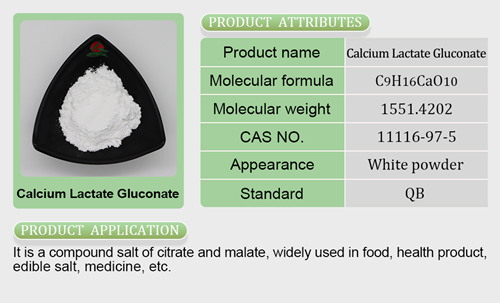

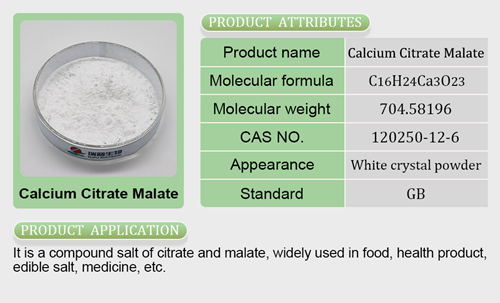

- Calcium Salt6 products

- Copper Salt1 product

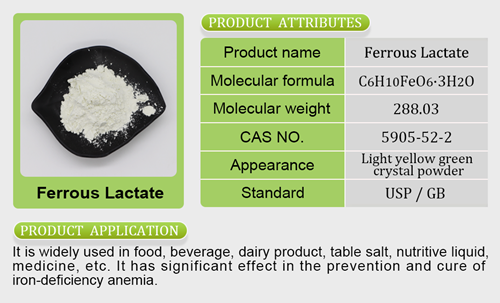

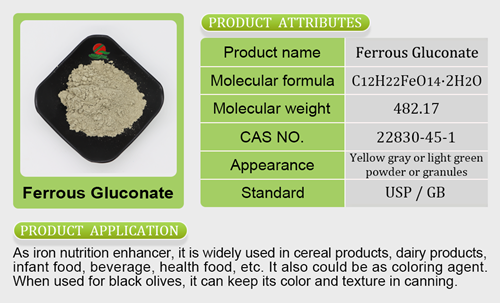

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products