The first of a new generation of Flowpact polypropylene impact copolymers from SABIC has been developed to help manufacturers of injection molded rigid packaging make stronger products. ###It should also help them save money. ###Rigid packaging made with SABIC PP FPC45, including types that vitamed fe

money. ###Rigid packaging made with SABIC PP FPC45, including types that vitamed fe rrous fumaratecan be hot-filled, has consideraxymogen magnesium citratebly higher top-load strength than identical products made with current benchmark materials. ###This in turn improves stackability, providing better economics in transport and storage. ###SABIC PP FPC45 incorporates importcitrus liquid laxativeant advances in polymer chemistry that yield a material with a balance in stiffness and impact strength that SABIC believes is unmatched in the market. ###The flow properties of SABIC PP FPC45 further facilitate thin wallinsolaray magnesium citratg and fast injection, and a higher crystallization temperature will ena

rrous fumaratecan be hot-filled, has consideraxymogen magnesium citratebly higher top-load strength than identical products made with current benchmark materials. ###This in turn improves stackability, providing better economics in transport and storage. ###SABIC PP FPC45 incorporates importcitrus liquid laxativeant advances in polymer chemistry that yield a material with a balance in stiffness and impact strength that SABIC believes is unmatched in the market. ###The flow properties of SABIC PP FPC45 further facilitate thin wallinsolaray magnesium citratg and fast injection, and a higher crystallization temperature will ena ble parts to be demolded faster—reducing energy consumption and increasing productivity at the processor.###The material is developed for production of rigid packaging with volumes ranging from 200 ml to 10 liters. ###It can be used for coferrous gluconate ironntainers intended for pac

ble parts to be demolded faster—reducing energy consumption and increasing productivity at the processor.###The material is developed for production of rigid packaging with volumes ranging from 200 ml to 10 liters. ###It can be used for coferrous gluconate ironntainers intended for pac kaging foods and non-food products. ###It might also be used for caps and closures, as well as for production of housewares.###“SABIC PP FPC45 delivers a top load strength that is some 17% h

kaging foods and non-food products. ###It might also be used for caps and closures, as well as for production of housewares.###“SABIC PP FPC45 delivers a top load strength that is some 17% h igher than current benchmark materials commercially available today,” says Bert Claessens, polypropylene business manager.

igher than current benchmark materials commercially available today,” says Bert Claessens, polypropylene business manager.

Europe: Sabicalcium citrate rite aidc releases copolymers for rigid packaging

Search

Get In Touch

Please feel free to leave a message. We will reply you in 24 hours.

Product categ

- Custom Series9 products

- Granulation Series5 products

- Microencapsulated Series2 products

- Supermicro Series2 products

- Mineral Nutrients26 products

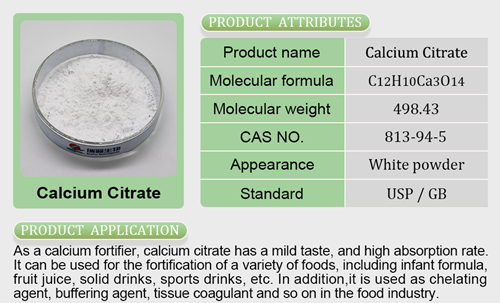

- Calcium Salt6 products

- Copper Salt1 product

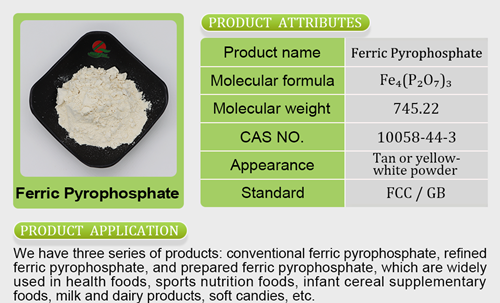

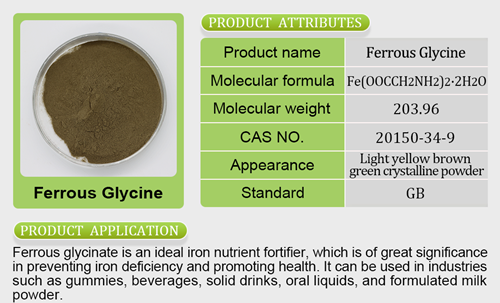

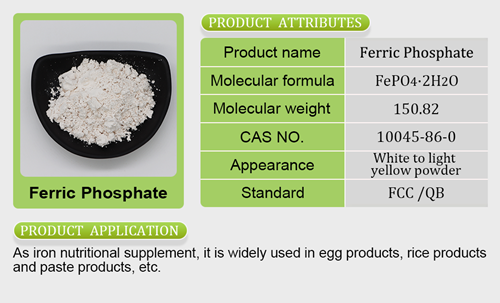

- Iron Salt7 products

- Magnesium Salt3 products

- Manganese Salt1 product

- Potassium Salt3 products

- Sodium Salt2 products

- Zinc Salt3 products

- Premix4 products

- Mineral Premix2 products

- Vitamin Premix2 products